There is no doubt that COVID-19 has drastically impacted the world and ultimately life as we know it. The means in which we go to work, run our errands, and even what we buy have all changed. Yes, thanks to COVID-19 and the subsequent shutdowns of factories, the super markets of America have been looking pretty bare this summer. As demand for basic household goods skyrocketed in the months of May and June, retailers and manufacturers alike were caught in a balancing act trying to juggle a pandemic, their owner workers’ safety, and the growing demands of consumers. A challenging task no doubt, it came as no surprise when stores eventually began just placing “Out of Stock” signs across whole aisles.

Nowhere was this struggle to upkeep production more evident than in the category of cleaning/sanitary products. Products like toilet paper, disinfectants, and the newly popularized personal protective equipment (PPE) all quickly flew off the shelves as consumers began to stockpile these items in an attempt to prepare for the worst. Although this did result in the disappearance of these items from store shelves, we have seen a slow but steady resurgence of most sanitary items. I say most because there is still one product category that is virtually impossible to find. No, it’s not toilet paper, at least not anymore. I am instead talking about disinfectant wipes. What makes disinfecting wipes so special and why are some industry experts predicting that American shoppers may not be seeing them back on the shelves any time soon?

The Devil is in the Detail

With the business world back to a semi-normal working situation and products back on the shelves, many are beginning to wonder why we are not also seeing a resurgence in disinfectant wipes. In May 2020, Clorox chairman and CEO Benno Dorer said the company had increased its production of disinfectant products by 40%, however this has only put a small dent in the growing demand as industry reports showed a spike of up to 500% for the product category. Failing to deliver on the industry’s promise of new supply as early as July or August has left consumers frustrated with big brands like Lysol and Clorox. Especially since toilet paper, a seemingly comparable item that experienced the same spike in demand, has made its way back to store shelves. However, upon closer analysis, one will begin to see why CEO Benno Dorer is now predicting that Americans may not see their demand fully met until the year 2021.

"Disinfecting wipes, which are the hottest commodity in the business right now, will probably take longer because it's a very complex supply chain to make them," Dorer said.

Unlike toilet paper, who’s manufacturing is 90% domestic to North America, the supply chain for disinfecting wipes spans across the globe. Thus, before factories can even begin production, they must first wait on the sourcing of raw materials from overseas. This can result in as long as a 4-week delay in production. Sadly, the troubles with disinfectant wipes’ raw materials do not end there. The toilet paper industry has also been fortunate enough to be in an ideal situation where the demand for their finished product is increasing while the demand for the raw materials used to make these products has been decreasing. Pulp, the main raw good used in the production of toilet paper is no longer at its peak demand. With offices closing and employees working at home the need for office paper began to fall and thus production decreased. Freeing up the supply of pulp, the shared raw material between office and toilet paper. Ironically it appears that the main issue halting the production in disinfectant wipes also spawns from the scarcity of a shared raw material.

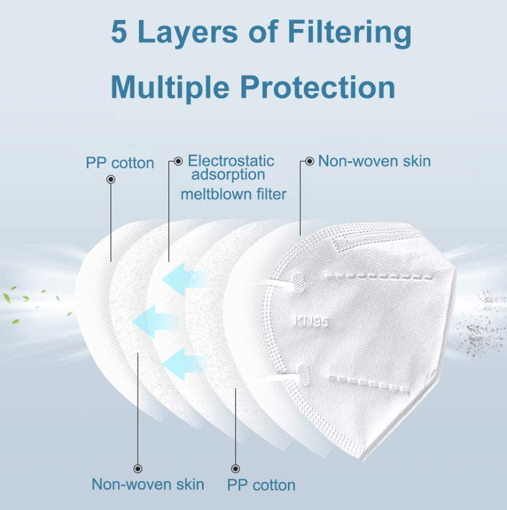

If you read our blog about how to make your own disinfecting wipes, then you would know that the wipes used to make the product are not actually made from paper. In fact, most disinfecting wipes use polyester spunlace non-woven fabric for the creation of their products. A popular choice among manufacturers as it is a durable synthetic material that mimics the softness and feel of traditional textiles. At last this also includes the use of the material in the creation of PPE such as masks and medical gowns.

Unfortunately for manufacturers of disinfectant wipes, and their consumers, the global demand for PPE does not seem to be slowing down anytime soon. Without a steady supply of raw materials even the industry’s new prediction of a 2021 return seems like an achievable goal. No doubt it will be interesting to see how these suppliers change their production process in hopes of meeting their new demands.

However, not all disinfectant suppliers are facing the same issue. Thanks to the emergence of third-party manufacturers as a response to the noticeable shift in consumer behavior. With more and more businesses counting on disinfectant wipes to keep their employees and customers safe, ICC actually worked to source its own house brand of disinfectant wipes. As for the major brands like Lysol and Clorox, it might be a little bit longer before consumers can see them readily available and stocked in the stores again.

Looking for disinfectant wipes? You can find them and many other COVID Essentials at iccbusinesproducts.com.

Still in the mood for reading? Check out our blog to read other interesting lists and insights into the business world.